In today’s interconnected and unpredictable world, supply chains face unprecedented disruptions—from geopolitical conflicts to climate change and cyberattacks. Businesses must rethink their approach to resilience. This post explores how historical lessons, modern technologies, and strategic planning are converging to build adaptive and future-proof supply chains.

Understanding Supply Chain Volatility

Volatility stems from various global challenges. Common sources include:

- Geopolitical tensions (e.g., trade wars, sanctions)

- Climate-related events (e.g., floods, droughts)

- Pandemics and health crises

- Cyber threats and infrastructure vulnerabilities

- Fluctuating consumer demand and market conditions

These factors create a complex environment where traditional linear supply models struggle.

Historical Context: Lessons from the Past

1. World War II Logistics Innovations

During WWII, nations developed vast logistics systems to move troops and supplies. The emphasis on decentralized distribution and localized sourcing remains relevant today.

2. Oil Crisis of the 1970s

The energy embargo forced companies to diversify suppliers and explore alternative transportation routes—early signs of adaptive sourcing.

3. 2008 Financial Crisis

Liquidity shortages exposed the fragility of just-in-time (JIT) systems. Many businesses began to consider just-in-case models.

Key Pillars of Resilient Supply Chains

| Pillar | Description |

| Diversification | Sourcing from multiple suppliers/regions to reduce dependency |

| Digitization | Using AI, IoT, and blockchain for visibility and predictive analytics |

| Sustainability | Eco-friendly logistics, circular economies, and energy-efficient transport |

| Agility & Flexibility | Ability to pivot quickly to market changes or emergencies |

| Localization | Nearshoring or reshoring to reduce lead times and geopolitical risk |

| Collaboration | Strong supplier and stakeholder partnerships with shared contingency plans |

Digital Tools Driving Supply Chain Resilience

AI and Machine Learning

- Predict potential disruptions

- Optimize inventory and routing

- Forecast demand more accurately

Blockchain

- Enables secure, transparent tracking of goods

- Helps in verifying origin, compliance, and authenticity

Internet of Things (IoT)

- Real-time tracking of shipments

- Remote monitoring of warehouse operations

Cloud-Based Platforms

- Centralize data

- Enhance remote collaboration

- Improve decision-making agility

Example: IBM’s Sterling Supply Chain Suite provides visibility, intelligence, and orchestration tools.

Adaptive Strategies Businesses Are Using

- Dual-Sourcing Critical Materials

Reduces risk if one supplier is unavailable. - Scenario Planning & Simulation Tools

Companies simulate potential disruptions to prepare alternatives. - Flexible Manufacturing Systems

Multi-skilled labor and adaptable equipment help switch production rapidly. - Buffer Inventory

While JIT is still popular, many firms now maintain strategic stock for critical items. - Supplier Risk Assessment

Evaluate political stability, compliance, and financial health of suppliers.

Case Study: Toyota’s Recovery Post-2011 Tsunami

After the 2011 Japan earthquake and tsunami, Toyota implemented:

- Detailed mapping of suppliers and sub-suppliers

- Risk scoring models

- Supplier training in crisis management

This preparedness enabled quicker recovery from future shocks, including COVID-19.

Regionalization vs. Globalization in Modern Supply Chains

Regionalization is gaining traction:

- Increases speed to market

- Mitigates cross-border delays

- Strengthens regional economies

However, globalization still provides access to cost advantages and diversified markets.

Hybrid models are emerging, blending global reach with local responsiveness.

Policy and Regulation Influence

Governments now play a larger role in shaping supply chains:

- U.S. CHIPS Act: Boosts domestic semiconductor production

- EU Supply Chain Due Diligence Law: Enforces ethical sourcing and labor practices

- India’s PLI Scheme: Encourages manufacturing within national borders

Businesses must monitor and adapt to such evolving regulatory landscapes.

Challenges in Building Resilient Supply Chains

- High upfront costs for diversification and digitization

- Potential inefficiencies in localized or redundant systems

- Complexity of managing multiple suppliers and data systems

- Resistance to change in legacy corporate cultures

Solution: Incremental transformation with clear ROI tracking and leadership buy-in.

Opportunities for the Future

- Circular economy models for sustainable product lifecycle management

- Digital twins for simulating supply chain behavior in real-time

- AI-driven procurement to predict and fulfill dynamic sourcing needs

- Cloud ERP systems for unified control and rapid scaling

“Resilient supply chains aren’t built overnight—they are engineered through continuous learning, investment, and collaboration.”

Frequently Asked Questions (FAQs)

- What is supply chain resilience?

Supply chain resilience refers to the ability of a system to anticipate, respond to, and recover from disruptions while maintaining functionality and minimizing impact. - Why is diversification important in supply chains?

Diversification minimizes dependency on single suppliers or regions, reducing risks from local disruptions like natural disasters or political instability. - How can technology improve supply chain resilience?

Technologies like AI, IoT, and blockchain enhance visibility, forecast accuracy, and traceability, helping businesses respond faster to disruptions. - What are the main challenges of resilient supply chains?

Cost, complexity, data integration, and cultural resistance are key barriers to implementing resilient systems. - How does globalization affect supply chain adaptability?

While globalization offers cost benefits, it introduces risks such as geopolitical tensions and longer lead times—hence the need for a hybrid model.

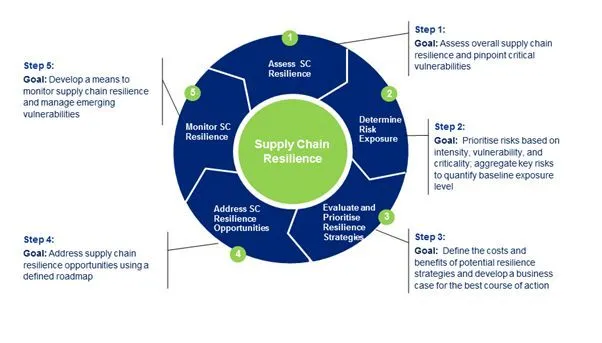

Key Pillars of Resilient Supply Chains

Building a resilient supply chain requires more than just reacting to disruption—it calls for strategic foresight and integrated frameworks. Six core pillars underpin this adaptability. Diversification is crucial, as relying on a single supplier or region creates vulnerability; firms now actively source from multiple vendors across varied geographies. Digitization enables real-time data access through technologies like IoT, AI, and blockchain, offering predictive insights and visibility across every link in the chain. Sustainability is no longer optional—supply chains must align with environmental goals, from reducing emissions in logistics to utilizing renewable materials.

Conclusion:

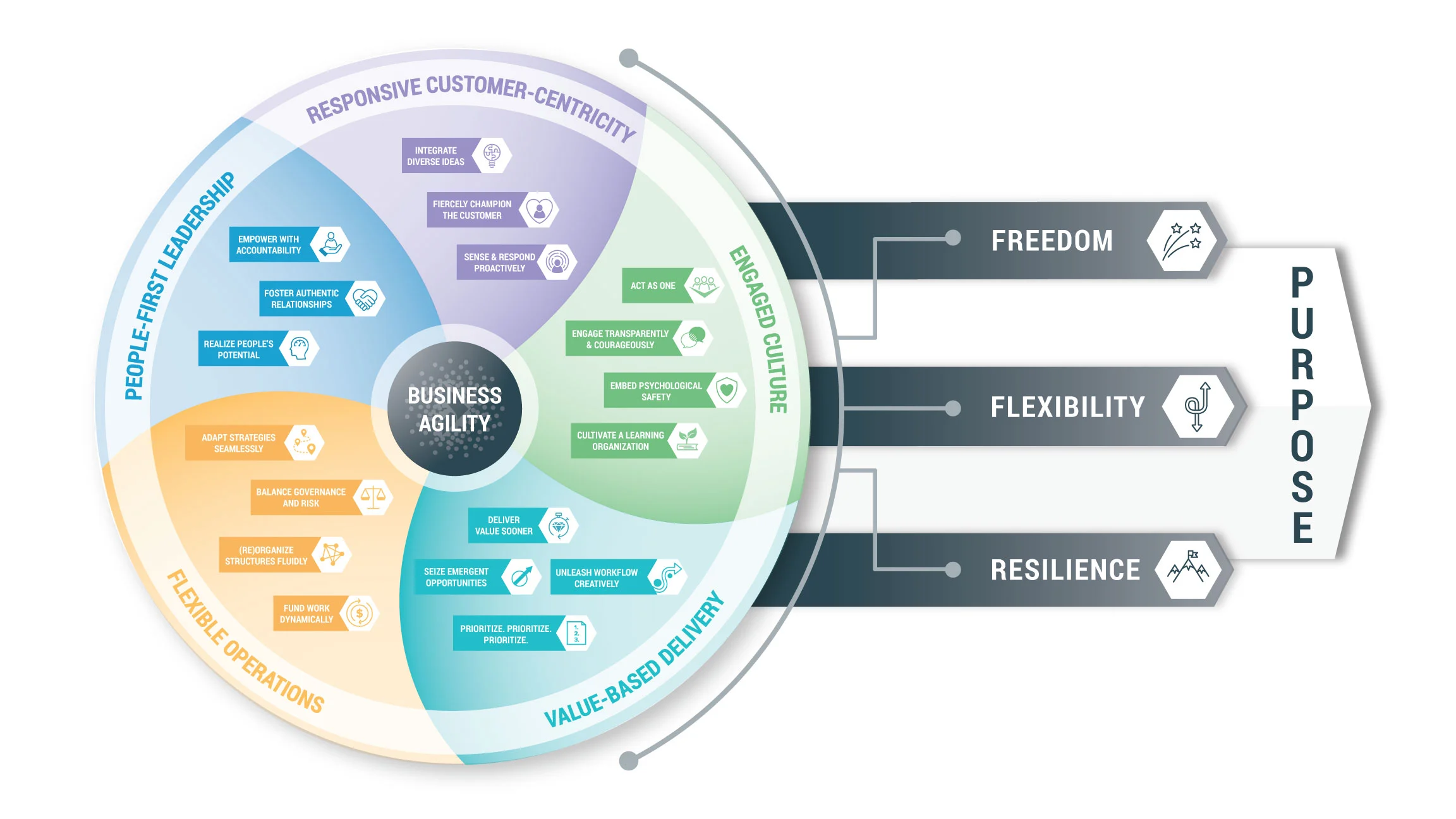

In an era defined by volatility—climate disruptions, geopolitical tension, cyber threats—resilience has emerged as the cornerstone of modern supply chain strategy. It’s not merely about recovering from crises but proactively anticipating them. Companies that embed resilience into their DNA—through diversified sourcing, digitized networks, and agile response mechanisms—are not only better equipped to navigate disruption, they also seize competitive advantage by responding faster and smarter. These businesses are moving away from rigid, cost-optimized models toward systems that balance efficiency with flexibility. Importantly, the transition to resilient supply chains is also aligned with broader corporate responsibility goals, from environmental sustainability to ethical labor practices, ensuring long-term viability and trust.

At Apache Plaza, we believe that studying the evolution of supply chains—through both historical lenses and modern business innovations—equips leaders with the insight to build truly future-ready systems. As global challenges persist, supply chains must shift from being vulnerable liabilities to strategic assets. The organizations that prioritize investment in resilience today are the ones that will shape tomorrow’s stable, sustainable trade networks. For more insights on how businesses are navigating technological and ethical shifts, explore our articles on digital critical thinking and algorithmic ethics.